The world’s first 120-ton electric mining dump truck with AC drive and CATL batteries successfully rolled off the assembly line at Xiangtan Electric Manufacturing Co. Ltd. (XEMC) on June 23 and is slated to enter mine trials in July. As a shining example of the intelligent electrification era, this product will be used for transportation in open-pit mines, boosting the mining industry’s progress towards low-carbon, energy-efficient products and environmental protection.

Excellent performance is enabled by innovative technology.

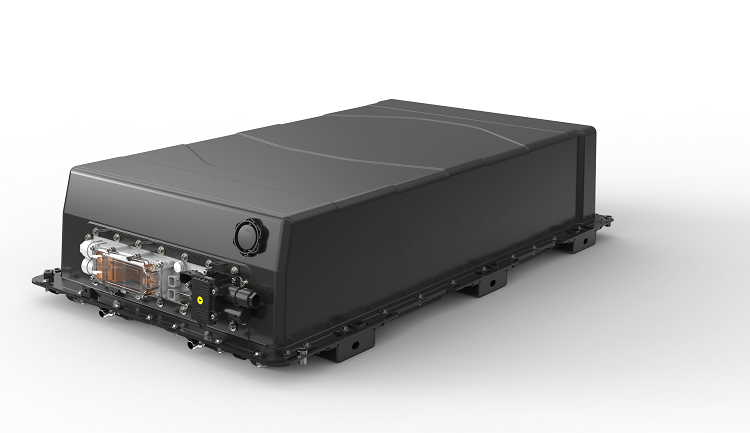

The trucks are outfitted with CATL’s large-capacity, ultra-safe lithium iron phosphate traction batteries, which, thanks to high-voltage, fast-charging technology, can fulfill the requirement for high-power charging.

The batteries with unique cell-to-pack (CTP) technology have a high energy density and can work continuously for eight hours after being fully charged. The smart BMS can monitor the battery’s health status 24 hours a day, seven days a week and properly estimate the charging state.

The intelligent temperature management system ensures that the battery can operate efficiently between -30°C and 60°C, allowing electric mining dump trucks to operate in all weather situations.

Dependable and safe

CATL’s traction batteries are safe and reliable thanks to carefully selected raw materials and intelligent design, as well as multi-level protection, an autonomous manufacturing process, and extensive testing and verification.

Electric mining dump trucks are typically used in difficult situations with a lot of dirt and dust. As a result, the batteries must meet stringent specifications in order to remain dustproof and work well. CATL’s traction batteries have received the industry’s highest IP68 classification, indicating that they are protected against erosion and dust in a mining environment, allowing them to operate in a reliable way under complex conditions.

Green energy is both cost-effective and environmentally friendly.

In comparison to 100-ton fuel trucks, the 120-ton electric mining dump truck has achieved zero emissions, lowering carbon emissions by 1,500 tons per vehicle per year. Thus, the energy cost is lowered by 50%, and the entire maintenance cost is decreased by 20%.

Furthermore, the truck produces little noise and is easy to operate. In the future, CATL will collaborate with other partners to encourage a broader use of traction batteries in commercial vehicles, ushering in the era of intelligent electrification.

Source: https://www.catl.com/en/news/658.html